Food labelling

Practical Action

Types of food label

All food products should be labelled. The type

of label used varies according to the type of

product, the packaging container, individual

preferences and local availability of labels. The

most common (and cheapest) type of label is

the paper label that is glued onto the container.

Self-adhesive labels are also available but may

be more expensive.

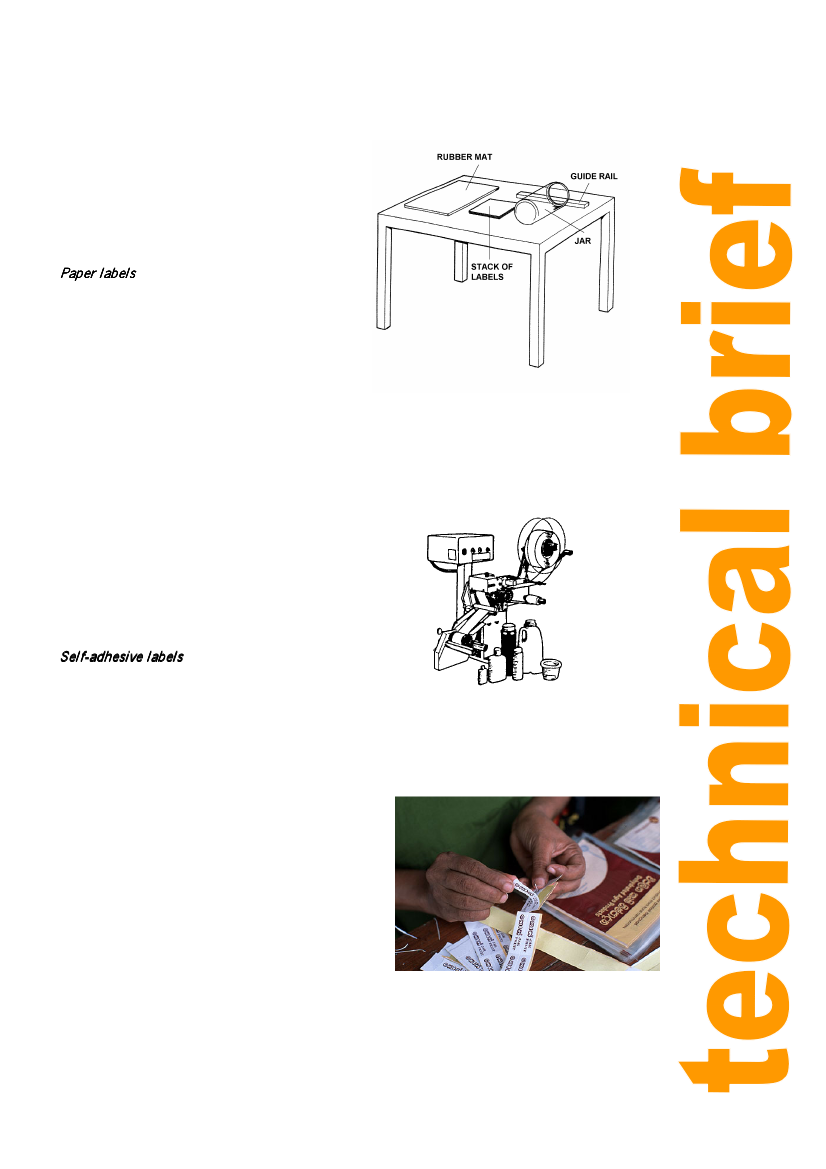

Paper labels are made out of plain paper. The

information can be written by hand, or it may be

printed if this facility is available. The labels are

glued and applied to the containers by hand.

The best way to apply these labels is to have a

guide rail affixed to the work surface. The pile

of labels is placed face down beneath the guide

rail. The top label is glued and the container is

rolled over the label, with the top pressed up to

the guide rail. The container is then rolled over

a rubber mat, to firmly press the label onto the

container. Figure 3 shows a simple frame that

can help in this operation. Labelling equipment

is available to apply the labels more quickly and

to give a better finish.

Figure 2: A table used to fix labels.

Water soluble glues such as starch or cellulose

based glues are best for returnable containers,

allowing labels to be removed easily. Water

soluble glues can loose adhesion in humid

climates so non water-soluble glues, made from

plastic polymers, can be used.

Self-adhesive labels are already gummed and just

need to be stuck onto the container. Care should

still be taken to ensure the label is applied neatly.

Small labelling machines are available that can

apply the labels to the product. The type shown

in Figure 4 can apply 30-40 labels per minute.

Figure 3: A powered labelling machine.

Basic generic label design

If a range of products is being produced it is

possible to use a common label design that can

then be adapted for each product line. For smaller

producers this helps keep the design and print

costs down.

There should be some standard artwork or brand

image and standard information on the

manufacturer can be included with a blank area left

for further information about the product to be

added at a later stage. The product can be

identified either by writing on the label or by using

stickers containing the relevant information.

Figure 4: labelling dried jack fruit in Sri

Lanka. Photo: Practical Action / Zul.

2